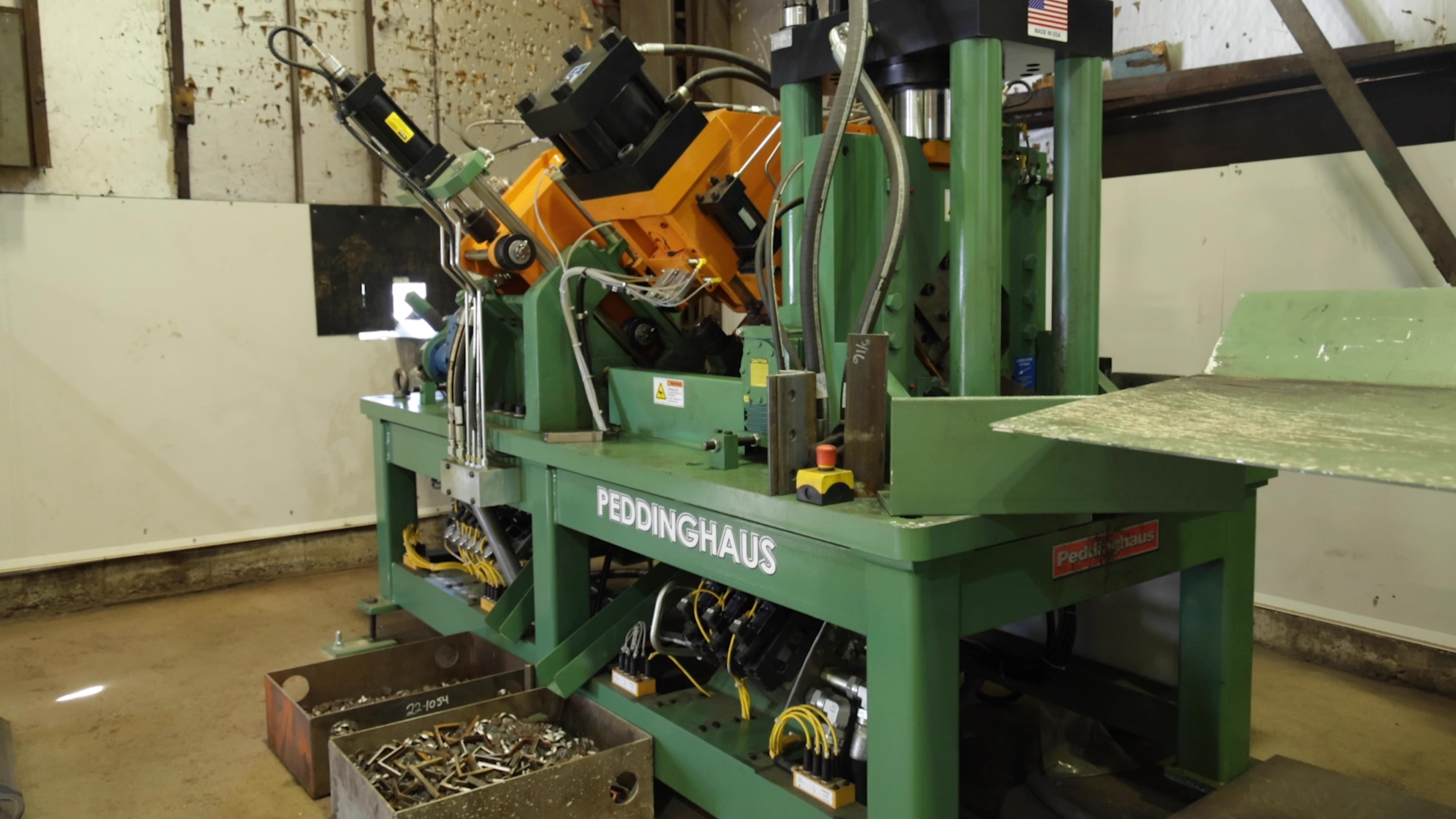

Industrial Resources recently added a piece of machinery to our 37,440-square-foot steel fabrication facility that adds increased efficiency to the steel fabrication process. The Peddinghaus Anglemaster-643 was introduced to the team, and after thorough training, we can use the anglemaster to its full potential. Continue reading to hear from Industrial’s Manager of Fabrication, David Ward, on how the anglemaster increases efficiency resulting in a faster, more accurate product for our customer.

What led to purchasing an anglemaster?

David Ward: In the years past at Industrial Resources, the way they processed angles was that they had a manual shear. They would manually lay them out, and then another employee would punch them. In an effort to be more cost-effective, we started looking at other avenues and other machines that could do that for us. We did some due diligence, looked at several different units, and settled on the Peddinghaus Anglemaster-643, which is a computer-driven angle line capable of generating all of our angle clips off of the computer and eliminating that manual process that we used to use.

How does the anglemaster increase efficiency?

David Ward: We averaged about 10 minutes per angle or clip using the old way. Now, we do it conservatively in a minute. So, we save a lot of money just by running them all in that line. It makes us more efficient. One guy can feed the whole shop for three shifts, so we’ve saved a lot of time and a lot of money by putting that machine in. We’re never waiting on a clip. The accuracy is always spot on.

Why specifically did you choose the Peddinghaus Anglemaster-643?

David Ward: We settled on the anglemaster from Peddinghaus because we already had a Peddinghaus drill line. So, it synchronized the computer programs, it’s the same program, so it gave us some efficiencies in that manner. Plus, it is probably the best angle line on the market.

How does the anglemaster work? Describe a general project.

David Ward: We get files sent from the engineering group, detailed drawings with NC1 files, and those files are loaded onto the anglemaster computer. the operator pulls the file up for any given drawing. He gets the material that he needs for that specific piece. He runs it, shears it, cuts it, punches it, or whatever the case may be. Once it’s done, he marks it, labels it, and we send it down to the shop.

Why should a potential customer choose Industrial Resources to complete a project?

David Ward: Industrial Resources is a full-service manufacturing facility supporting mainly coal, oil, and gas, and aggregate industries. We have a full-service fabrication shop backed by a full engineering staff, and also we have a sister company that can provide field services as well to do all of our installations.

We have quality out the back door. Through our inspection process, both at the machine and in our fit-up area, you’re not going to get a piece in the field that doesn’t bolt up, and that’s not going to be made to specifications.

MAKE THE SAFE CHOICE, CHOOSE INDUSTRIAL | CONTACT US

For over 75 years, Industrial Resources has been recognized for its outstanding commitment to the highest quality and safety standards in steel fabrication, engineering, and detailing. Our dedication to customer service is the reason so many companies repeatedly choose us for their steel fabrication and erection needs.

Industrial Resources adheres to the highest of standards set by the AISC. Contact us today to get your project started!